HAS offers quality spare parts for elevator equipment

The well-known Turkish company HAS occupies a leading position in the market of elevator equipment. Especially widely their products are distributed in Europe. Every day, millions of people use lifting equipment from this manufacturer, trusting him with their safety and comfort. The most convenient and fast movement - these are the main goals for the implementation of which they strive for in the company.

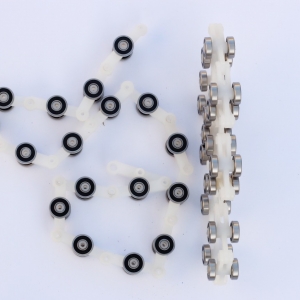

Innovative developments that have been proposed by the HAS team are used throughout the world. In Ukraine, the supply of components from the famous Turkish supplier is engaged in the company VLC Lift. The range of product selection is very wide. Currently this is:

complete lifts;

lift cabins;

elevator doors;

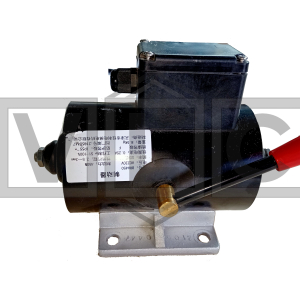

winches;

hydraulic systems;

accessories for elevators.

All parts are designed for different degrees of load capacity and the widest possible functionality. In addition to the main activity - the production of quality products for elevator equipment, the company provides services for the implementation of installation and repair work. All members of the HAS team are highly qualified specialists who know their business and cope with any kind of installations and breakdowns of both passenger elevators and large-sized cargo lifts.

Production of the company HAS is adjusted to the production of high-quality spare parts for elevator equipment

HAS began its activities in the distant 1980, with the development of its first plastic and rubber components. Over the years, the production was as focused as possible on the field of elevator engineering, and today is a streamlined process that is constantly being optimized through the introduction of new ideas and developments.

All manufactured products are carefully checked. Due to the presence of a large production area of 7,200 m², the team of professionals has all the capabilities to test large cargo cabins and other spare parts for large lifts. The company’s management also took care that the production unit had its own robotic laser systems, painting lines and special powerful machines for cutting and bending metal.